Choosing VL Plank (interlocking T&G) over Traditional Lap Siding (overlapping) is a choice between a "Modern Architectural" look and a "Classic/Colonial" look. While both are durable, VL Plank offers several distinct technical and aesthetic advantages.

Here is why you should choose VL Plank:

1. Modern "Flat" Aesthetic

Traditional Lap: Creates a "stepped" or "shingled" profile. It casts heavy shadows and has a very traditional, country-style appearance.

VL Plank: Sits flush (flat) on the wall. It creates a sleek, contemporary surface with clean "shadow lines" (V-grooves). It is the preferred choice for modern residential and commercial designs.

2. Hidden Fasteners (Blind Nailing)

Traditional Lap: Often requires "face-nailing" at the bottom of the board to prevent wind rattle, meaning nail heads are visible and must be painted over.

VL Plank: Designed for 100% hidden fixing. You nail through the tongue, and the next board’s groove completely covers the nail. The result is a clean, fastener-free finish that never shows rust streaks from nail heads.

3. Faster, More Accurate Installation

Traditional Lap: Installers must manually measure the "overlap" (exposure) for every single row using a gauge to ensure the lines stay level.

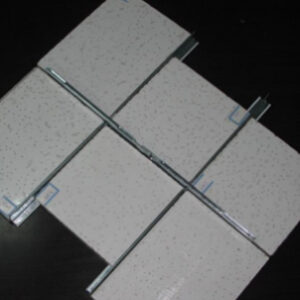

VL Plank: The interlocking T&G profile is self-aligning. Once your starter strip is level, every subsequent board clicks into the correct position. This significantly reduces installation time and human error.

4. Better Wind Resistance & "Rattle" Prevention

Traditional Lap: Because the boards only overlap, high winds can sometimes cause the bottom edges to "chatter" or rattle against the wall.

VL Plank: The boards are physically locked together on the long edges. This creates a much more rigid "monolithic" wall structure that is quieter and more secure in high-wind or cyclonic zones.

5. Vertical Installation Capability

Traditional Lap: Can only be installed horizontally. If you try to install it vertically, water will get behind the overlaps.

VL Plank: Because of the T&G seal, many VL systems are rated for both horizontal and vertical installation.

Vertical cladding is currently a major trend in modern architecture (the "Timber Slat" look).