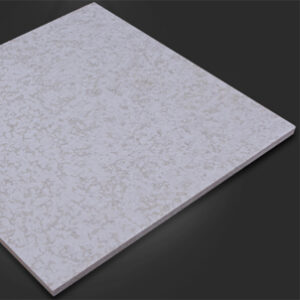

Magnesium Oxide (MGO) board is often referred to as a "next-generation" building panel and is an alternative to traditional drywall, cement board, and fiber cement board.

Magnesium Oxide (MGO) board is often referred to as a "next-generation" building panel and is an alternative to traditional drywall, cement board, and fiber cement board.

Here is a detailed overview of MGO partition board, including its properties and common uses:

🧱 What is MGO Partition Board?

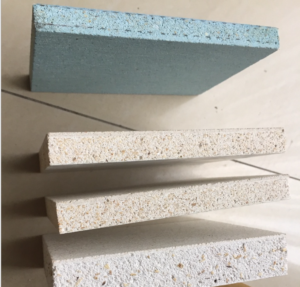

MGO board is a mineral-based green building material made from a combination of magnesium oxide (MgO), magnesium chloride, water, and various additives, often reinforced with fiberglass mesh. It is used extensively for interior and exterior wall partitions, sheathing, and backer board.

✨ Key Advantages and Properties

| Feature | MGO Partition Board |

| 🔥 Fire Resistance | Excellent (Non-Combustible). Often achieves a Class A fire rating and can provide fire resistance ratings from 60 minutes up to 4 hours, depending on the thickness and assembly. It does not produce toxic smoke when exposed to fire. |

| 💧 Moisture Resistance | Very High. It is inherently resistant to water, mold, and mildew. When submerged, good quality MGO boards maintain their structural integrity and generally do not swell or deteriorate, making them ideal for bathrooms and damp areas. |

| 💪 Strength/Durability | High. It is generally denser and more impact-resistant than gypsum drywall. |

| 🔇 Sound Insulation | Provides good acoustic dampening properties, which improves privacy in partition walls. |

| 🌱 Environmental Impact | Generally considered a green building material. It is often made from natural mineral components and is free from asbestos, formaldehyde, and other toxic chemicals. |

| 🛠️ Workability | Can be cut, sawed, drilled, and fastened using standard woodworking tools, similar to fiber cement or drywall. |

🛠️ Primary Applications for MGO Partition Boards

MGO boards are versatile and are commonly used in various areas, especially when fire resistance and moisture control are critical:

- Interior Partitions: Used as a strong, durable, and fire-resistant replacement for standard gypsum drywall in commercial and residential walls.

- Wet Area Backer Board: Excellent substrate for tiling in high-moisture areas like kitchens, bathrooms, and laundries, outperforming traditional cement boards in some aspects of water and mold resistance.

- Acoustic/Fire-Rated Ceilings: Used in assemblies that require specific fire-stop and sound-dampening ratings.

- Structural Sheathing: Used in exterior wall assemblies for added durability, fire protection, and as a structural component.

⚠️ Note on Waterproofing

While MGO board is highly moisture-resistant, just like fiber cement board, a dedicated waterproofing membrane must still be applied over it in areas subject to direct water exposure (like a shower recess) to ensure a complete, sealed, and code-compliant waterproof system.

More information, please visit at www.hocre-board.com or send message by whatsapp +86 15001321220

That's an excellent question, as the difference between "moisture-resistant" and "waterproof" is critical when choosing building materials like fiber cement board.

That's an excellent question, as the difference between "moisture-resistant" and "waterproof" is critical when choosing building materials like fiber cement board.

The primary risk associated with "free chlorides" in

The primary risk associated with "free chlorides" in  The "weeping" or "sweating" issue is a significant problem primarily associated with older-style

The "weeping" or "sweating" issue is a significant problem primarily associated with older-style  No,

No,

The question of whether

The question of whether  An

An  MGO Board Fire Resistance Official Ratings

MGO Board Fire Resistance Official Ratings

Yes, some types of

Yes, some types of

The best and safest way to clean your

The best and safest way to clean your