Choosing VL Plank (interlocking T&G) over Traditional Lap Siding (overlapping) is a choice between a "Modern Architectural" look and a "Classic/Colonial" look. While both are durable, VL Plank offers several distinct technical and aesthetic advantages.

Here is why you should choose VL Plank:

1. Modern "Flat" Aesthetic

Traditional Lap: Creates a "stepped" or "shingled" profile. It casts heavy shadows and has a very traditional, country-style appearance.

VL Plank: Sits flush (flat) on the wall. It creates a sleek, contemporary surface with clean "shadow lines" (V-grooves). It is the preferred choice for modern residential and commercial designs.

2. Hidden Fasteners (Blind Nailing)

Traditional Lap: Often requires "face-nailing" at the bottom of the board to prevent wind rattle, meaning nail heads are visible and must be painted over.

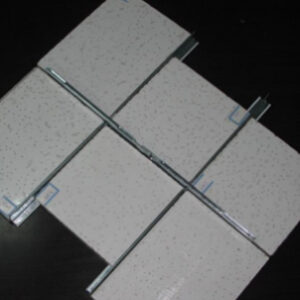

VL Plank: Designed for 100% hidden fixing. You nail through the tongue, and the next board’s groove completely covers the nail. The result is a clean, fastener-free finish that never shows rust streaks from nail heads.

3. Faster, More Accurate Installation

Traditional Lap: Installers must manually measure the "overlap" (exposure) for every single row using a gauge to ensure the lines stay level.

VL Plank: The interlocking T&G profile is self-aligning. Once your starter strip is level, every subsequent board clicks into the correct position. This significantly reduces installation time and human error.

4. Better Wind Resistance & "Rattle" Prevention

Traditional Lap: Because the boards only overlap, high winds can sometimes cause the bottom edges to "chatter" or rattle against the wall.

VL Plank: The boards are physically locked together on the long edges. This creates a much more rigid "monolithic" wall structure that is quieter and more secure in high-wind or cyclonic zones.

5. Vertical Installation Capability

Traditional Lap: Can only be installed horizontally. If you try to install it vertically, water will get behind the overlaps.

VL Plank: Because of the T&G seal, many VL systems are rated for both horizontal and vertical installation.

Vertical cladding is currently a major trend in modern architecture (the "Timber Slat" look).

A

A

The type of product you are describing is most commonly known as

The type of product you are describing is most commonly known as

The description "

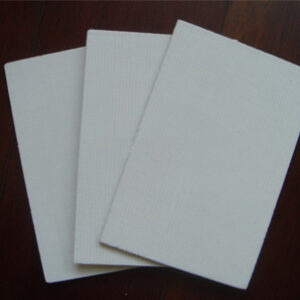

The description " The description "Sanded & slightly rough surface fibre cement board" refers to a specific, highly textural category of architectural cladding favored for its authentic, mineral aesthetic and tactile quality.

The description "Sanded & slightly rough surface fibre cement board" refers to a specific, highly textural category of architectural cladding favored for its authentic, mineral aesthetic and tactile quality. Tongue and groove (T&G) fiber cement plank is an innovative type of fiber cement siding specifically engineered to facilitate easier, quicker, and cleaner installation compared to traditional lap siding.

Tongue and groove (T&G) fiber cement plank is an innovative type of fiber cement siding specifically engineered to facilitate easier, quicker, and cleaner installation compared to traditional lap siding. This product combines high performance with sophisticated design, resulting in a facade material that is both durable and visually dynamic.

This product combines high performance with sophisticated design, resulting in a facade material that is both durable and visually dynamic.

That is a common and frustrating issue with painting any cementitious surface, including

That is a common and frustrating issue with painting any cementitious surface, including  Magnesium Oxide (MGO) board

Magnesium Oxide (MGO) board That's an excellent question, as the difference between "moisture-resistant" and "waterproof" is critical when choosing building materials like fiber cement board.

That's an excellent question, as the difference between "moisture-resistant" and "waterproof" is critical when choosing building materials like fiber cement board.