No, MgSO4 (sulfate-based) boards and MgCl2 (chloride-based) boards generally have the same high fire rating in their initial, dry state. The difference lies in the long-term stability of that rating in real-world, high-humidity applications.

No, MgSO4 (sulfate-based) boards and MgCl2 (chloride-based) boards generally have the same high fire rating in their initial, dry state. The difference lies in the long-term stability of that rating in real-world, high-humidity applications.

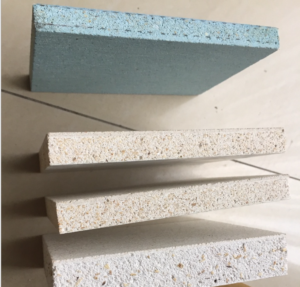

Both types of boards are built primarily on Magnesium Oxide (MgO) cement, which is inherently non-combustible

- Core Fire Rating is Identical

In laboratory tests, both MgSo4 and MgCl2 boards typically achieve the highest non-combustibility ratings:

- Non-Combustible Classification: Both are classified as Non-Combustible (e.g., Class A in ASTM E84 or A1 in EN 13501-1).

- Flame Spread and Smoke: They both usually achieve a Flame Spread Index of 0 and a Smoke Developed Index of 0 (or close to it) under ASTM E84 testing.

- Mechanism: Their fire resistance comes from the MGO mineral base and the water chemically bound within the cement. When heated, this bound water is released as steam, which helps cool the surface and block the spread of fire

- Stability of the Fire Rating (MgSo4Advantage)

The major difference is how well each board maintains its fire rating when exposed to moisture over the lifetime of a building:

| Feature | MgCl2 Board (Chloride-Based) | MgSO4 Board (Sulfate-Based) |

| Moisture Absorption | High. Chloride ions are highly hygroscopic (they attract and absorb moisture from the air). | Low. Sulfate is far less hygroscopic than chloride. |

| Corrosion Risk | High. Leaching chloride ions corrode steel studs and fasteners, compromising the wall assembly's structural integrity, which can lead to premature failure in a fire-rated assembly. | None. Non-corrosive to steel. The structural integrity is maintained. |

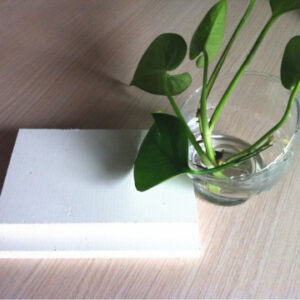

| Dimensional Stability | Poor in high humidity (prone to warping and swelling). This can cause gaps in fire-rated joints and compromise the assembly. | Excellent. Maintains dimensional stability, preserving the integrity of the fire-rated assembly. |

Conclusion: While both boards have an excellent fire rating when new and dry, MgSo4boards are significantly more reliable for maintaining that fire rating in high-humidity or exterior conditions because they do not absorb moisture, corrode fasteners, or degrade the way MgCl2 boards do.

More information, please visit at www.hocre-board.com or send message by whatsapp +86 15001321220

The question of whether

The question of whether  An

An  MGO Board Fire Resistance Official Ratings

MGO Board Fire Resistance Official Ratings

Yes, some types of

Yes, some types of